-

Phone

86-24-54112666

-

Address

No. 23, Pacific Industrial City, Economic Development Area, Fushun, Liaoning, China

-

E-mail

Magnetic Metal Sorting System for Crushed Recyclable Dry Scraps

China Magnetic Metal Sorting System for Crushed Recyclable Dry Scraps, Find details about China Magnetic Metal Sorter, Scrap Metal Recycling from Magnetic Metal Sorting System for Crushed Recyclable Dry Scraps - Fushun Ejet Magnetic Equipment Co., Ltd.

Description

- Model NO.: ECS-150

- Application: Hardware Fitting, Electronic Component, Auto Part, Ore, Tea, Meat, Aquatic Product, Vegetable, Grain

- Item: Recyclable Metal Recovery/Sorting

- Motor: Nord or Siemens Import Germany Motor

- Bearing: NSK Reliable Shaft

- Application Material: Recovery Metals Scrap From Dry Waste Crush Line

- Transport Package: Export Package for Metal Processing System Line

- Condition: New

- Sorting Standard: Quality

- Application System: in Bulky-Waste Crush Line for Matal Separate

- Belt: Forbo Siegling with Corrugated Edges

- Reducer: Schneider

- Trademark: JSYY/EJET

- Origin: Chinese Northeastern Heavy Industry Base

Recyclable scrap metals sorting system

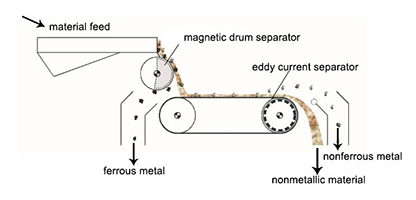

Scap metal sorting system in bulky-waste crush line to ensure the optimum recovery of valuable metal, ferrous and nonferrous, coarse or fine from shredded city recyclable waste. the effcient and effectivily magnetic metal sorting equipment composed by 3 parts

1.High intensity magnetic sorting equipment :removing ferrous metals(iron/steel) from shredder residue and split into two different fractions.to purify free-flowing powders and granular materials or concentrate and reclaim products in material.

2.An efficiently and accurately Eddy Current aluminium/copper separator:repel non-ferrous metals(such as aluminum, die-cast metal, copper,zinc and other value metals)from incoming materials get the high levels of purity and highest value product.

This rugged, effective and reliable copper & aluminium eddy curent sorting equipment are increasingly used wherever separation of non-ferrous metals from a product stream(such as plastics, glass, electronic scrap, automobile shredder residue, bottom ash, foundry sand, trash, co-mingle recyclables etc). can give a more valuable product, whether the end use is in recycling, waste reduction, raw material production or any other process whereby separation is beneficial.

3.A vibrator conveyors:spreading out and further separating the remaining metals to allow the metal separator to work at its optimal efficiency get the ideal metal separation.

Innowdays More and more attention in the recycling of resources leading the nonferrous recovery equipment fast increasingly usage wherever separation of non-ferrous metals from a product stream(such as plastics, glass, electronic scrap, automobile shredder residue, bottom ash, foundry sand, trash, co-mingle recyclables etc). can give a more valuable product, whether the end use is in recycling, waste reduction, raw material production or any other process whereby separation is beneficial.

the working priciple for scrap metal sorting system who used in recyclable waste crush line:

Feature and Benefits for EJET`s eddy curren aluminum/copper sorting equipment:

- The Rare Earth Arched Rotor is even effective "popping" small aluminum/copper particles.

- Our new, high speed bearing design allows a 25% higher rotor speed for exceptional purity.

- The rotor can be operated in forward or reverse, accommodating different particle characteristics.

- EJET` Eddy Current rotors/pulleys/rollers are high tension, carbon fiber wrapped for low vibration and long life.

- A special splitter provides exceptional straightness for optimum plastic purity and yield.

- The splitter is adjustable in both angle & height to satisfy a range of belt speeds & particle sizes.

- PET flake process rates up to 2500 lbs/hr/ft of feeder width can be achieved.

- A 1.3 mm thin, abrasion resistant urethane conveyor belt maximizes the aluminum "pop".

- A vibratory feeder assures a controlled flake depth to enhance the separation performance,and sometimes a magnetic drum will be installated after the vibrating feeder to protect the precious nonferrous eddy current separation machine.

- The Control Cabinet include a belt speed tachometer.

| Model | Belt Width | Motor Power | Dimension (mm) | Weight | ||

| mm | Kw | Length | Width | High | Kg | |

| ECS-40 | 450 | 3.0/0.75 | 2080 | 1357 | 1100 | 1100 |

| ECS-65 | 650 | 4.0/1.5 | 3300 | 1500 | 1200 | 1200 |

| ECS-80 | 800 | 5.5/1.5 | 3300 | 1700 | 1200 | 1400 |

| ECS-100 | 1000 | 5.5/1.5 | 3300 | 1900 | 1200 | 1600 |

| ECS-120 | 1200 | 5.5/2.2 | 3300 | 2000 | 1200 | 1800 |

| ECS-140 | 1400 | 7.5/2.2 | 3620 | 2130 | 1587 | 2100 |

| ECS-150 | 1500 | 7.5/2.2 | 3420 | 2240 | 1530 | 2200 |

| ECS-180 | 1800 | 7.5/2.2 | 3300 | 2700 | 1200 | 2800 |

| the processing line for zorba recovery | complex metals recovery system for PET flakes purification |

| shredded refrigerator metal recovery processing system | steel slag scraps recycling processing plant |

The eddy current nonferrous sorter(ECS)are also an advanced metal sorting unit are useful in capable separating aluminium, copper, zinc ect nonferrous matal recovery from a variety of conveyed dry waste materials/recyclables such as:

| Separation aluminum/copper caps and rings from crushed glass bottles scrap | Recovery of aluminum/copper from crushed PET bottles | Effeciently and accuratly separation nonferrous from rubber scraps/powder |

| Beverage cans (aluminum/steel cans plastic/glass bottles) sorting from waste streams | Processing of aluminum molding sand in aluminum-shell-sand recycling lines |

For wood processing industry to Separate non-ferrous metals from wood waste |

Non-ferrous separators offer a cost effective method of recovering up to 98% of valuable material from rubbish and waste. It also improves the purity of non-ferrous auto scrap up to 98-99%.

Quality: 1. Magnetic Materials--NdFeB/rare earth Magnet.

2. Main Parts--Imported to Insure the best performance.

3. Ejet is a professional designer and manufacturer for 10 years.

Price : As we are the manufacturer, the most competitive price could be offered.

As a professional automation and separating systems manufactures for more than 10years,honesty, reliability, commitment and competence are our unchanged values.

Thanks to the superior suppliers (Nord,Simens &Schneider) ,well-equipped professional engineers and strong technical force, we keep our consistent high quality.

Strict quality checked for every machine before packing, engineers available to service machinery overseas, inaddition, there is not only after sales service support, but also technology support, "keep improing, persuing excellence" would be keep forever.

we can design and manufacture complete eddy current conveyor systems or simply furnish eddy current drumpulleys or any other piece of magnetic separation equipment,beside these,we can also supply air classification device and nomal conveying equipment to meet your requirements.

- eddy current nonferrous metals sorter

- permanent and electric magnetic separation equipment for iron or steel sorting

- wet and dry type magnetic separator

- Permanent magnet and electromagnetic lifting equipment

- drum/roller/pulley magnets

- chute magnets

- magnetic sweepers

- excellent quality and reasonable price magnetic cartridges/grate/rods or tubes

- Nomal transporting/feeding equipment:such as belt conveyor/trommel drum screen/vibrator feeders

- zig zag air classification machine

Any requirement please contact :

Jasmine Song

Fushun Ejet Magnetic Equipment Co., Ltd

NO.23 Pacific Industrial City,Economic Development Area

Fushun City,Liaoning Province,China

TEL: +86 24 54012777

MOBILE: +86